Vacuum Seal

Integrity Tester

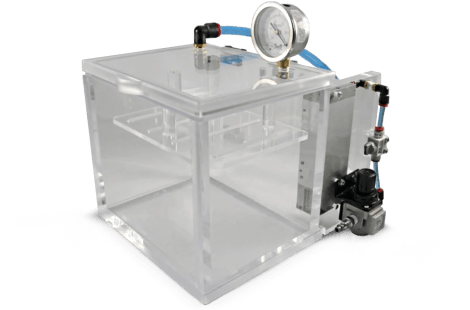

The simple and easy to use design of Modern's Seal Integrity Tester allows the user to perform continuous testing of packaging seals on the production line.

Contact us

Applications

The simulation of high altitude by the chamber checks seal integrity during trucking or air freight. The tester utilizes shop compressed air and a vacuum ejector to create a vacuum which is controlled by a manual pressure regulator. The reading is displayed on an analog gauge.

- Packaging machine set up

- Seal integrity testing

- Altitude simulation

- Material testing

- Quality control

Operation

The tester is set up by attaching local compressed air and a supply of water is added to the test chamber. It takes less than a minute for the operator to perform a vacuum test. Simply place the package in the chamber, close the lid and apply the vacuum. Once the chamber reaches the required setting, check for bubbles that would indicate a failed seal.

Vacuum Seal Integrity Tester Specifications

Test chamber is heavy gauge 18mm thick transparent acrylic

Air supply pressure required

up to 0.5 Mpa, 50 psi

Vacuum capability

up to 89 Kpa, 12 psi, 25inch Hg

Accuracy

± 1% of gauge reading